Sharpening Stones come in a bewildering variety of materials and styles. Today’s woodworker may well feel confused and overwhelmed. Water or oil, diamond or ceramic, man-made or natural? Which is the best stone to own?

We can start by answering the last question first: The best stone for all purposes does not exist. The best stone for a particular purpose does exist, however. The answer to the question, “which sharpening stone should I buy?” depends on what kind of sharpening is to be done. Let’s look at the strengths and weaknesses of commonly available stones:

Oil Stones

This class of stones use oil as a lubricant to keep the fine metal particles generated by the sharpening process from embedding into the surface of the stone. The metal particles are kept in solution and as a result do not “clog” or “glaze” the surface rendering it ineffective. Clogging is a potential problem with all stones.

- Manufactured oil stones are most commonly made from either silicon-carbide or aluminum-oxide. Natural oil stones are usually referred to as Arkansas stones, the softer variety, Washita.

- The coarse and medium grit oil stones will remove metal fairly rapidly. Because their surface is hard, oil stones wear very slowly and stay flat for a long time.

- The finer grit oil stones tend to remove metal slowly and are prone to excessive “glazing.”

- Some woodworkers object to the messiness of oil stones. Oily fingers and the fine project you are working on don’t mix! I have found that a mixture of water and dish soap works very well on oil stones. Because they are hard and slow to wear, oil stones are perfect for honing the narrow edge of a scraper blade.

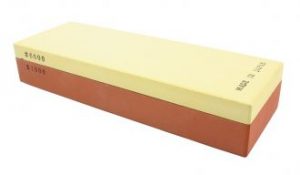

Water Stones

Man-made water stones have many advantages over other stones, and a few disadvantages. The advantages are:

- Very fast cutting action with a good “feel”.

- Wide variety of grits are available.

- Fine grit stones leave a polished, very sharp edge (difficult or unattainable with other stones).

- Generally affordable.

Disadvantages are:

- These stones wear rapidly and must be flattened periodically.

- Water stones are somewhat fragile and must be stored and handled carefully.

Many professionals agree that water stones are superior for sharpening chisels and plane irons, and for general shop use.

Ceramic Stones

Ceramic stones are normally sold only in very fine grits and are commonly used in applications where structural strength is necessary.

- They are quite hard and cut well when new but tend to become less effective over time and need to be re-surfaced to restore cutting action.

- The ultra-hardness of ceramic stones insures a flat, long lasting surface.

Diamond Stones

These “stones” are made by bonding diamond material to a flat metal substrate. When purchasing check to make sure the steel plate is flat.

- Diamond stones cut well and last a long time.

- They are the best choice for honing carbide tools.

- No lubricant is necessary and surface resists build-up.

- Diamond stones are generally expensive.

Woodworkers have different needs when it comes to sharpening stones. They also have different preferences about the “feel” of a stone. Try various stones and see what works best for you. Consider price, speed of cutting, quality or sharpness of edge, durability and usefulness. See our selection of sharpening equipment for more information.